A fellow Rover and MG enthusiast frustrated with problems after a PG1 rebuild asked if I could have a look. I made no promises and agreed to investigate.

Apparently the Box is a Diesel Spec PG1 one with a TorSen differential transplant. The problems, difficulties trying to select some gears. I've been suffering from a strong dose of nasty flu and only this week felt up to humping heavy PG1s about and made a start on Monday. In today's fine sunshine got stuck in and made better progress:~

![Image]()

![Image]()

First things first, found suitable length of rod and inserted that into the Roll Pin Hole of the Box's selector stub shaft :~

![Image]()

Input Shaft very stiff and difficult to manipulate. Impossible to select both 5th and Reverse. Neutral too very imprecise and like a "false" neutral. Even when able to select some gears, impossible to rotate the Input shaft to check :~

Tried again to select all six gears and failed miserably. Shaft very stiff and difficult to manipulate and impossible to select both 5th and Reverse.

Obviously something is not right so started to dismantle and investigate the internals. Removing the various Gearbox Casing Bolts, as soon as I put my socket on this 12mm casing Bolt, it moved.

![Image]()

Hmmm, suspect a stripped thread and so it proved. Someone had "modified it" :~

![Image]()

It should be easy to do that by hand. Could not do that even wearing a glove. Obviously something else not right.

![Image]()

Using a Clutch Plate on the Input Shaft for additional leverage, I was able to rotate the shaft in gear but, required some effort to do so :~

![Image]()

Yes, lots of tight things which should not be tight and impossible to do by hand.

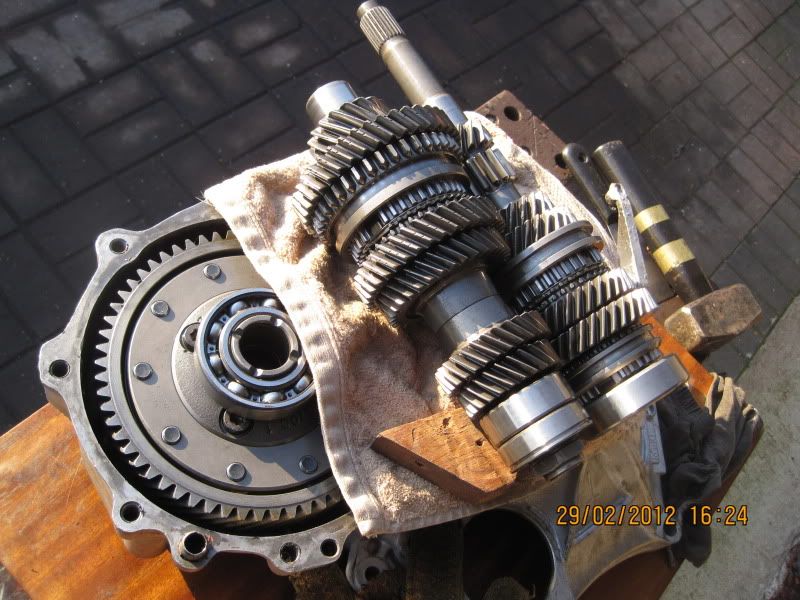

With all the 12mm casing Bolts removed AND the 14mm bolt which secures the Reverse Gear Idler shaft, I was able to seperate the Gearbox Casings to reveal the internals :~

![Image]()

![Image]()

![Image]()

All appeared well so far. With strong gloves, took a firm hold of the two Gear Clusters on their Shafts and the Selector Fork Assemblies and tried to lift them out. A good tug should lift them out ...NO WAY. Very firmly stuck. Using several lengths of rod under the shafts, by patient and careful leverage the assemblies did eventually lift a little at a time and then they were out. I have worked on over a dozen PG1s before and all were far less trouble to lift. Obviously something a bit tight somewhere. With the shafts removed, I looked at the new Input Shaft bearing. Cannot be certain but it did not look quite right. using my fingers it felt a little proud comapred to previous experience with these boxes. anyway, for good measure, used a bit of wood over the outer race and wit a club hammer, gave a few careful taps around its circumference. Not certain but, now it looked better. There was evidence here and close by of previous heavy handedness work on this box. Noticed a few other evidence marks too :~

![Image]()

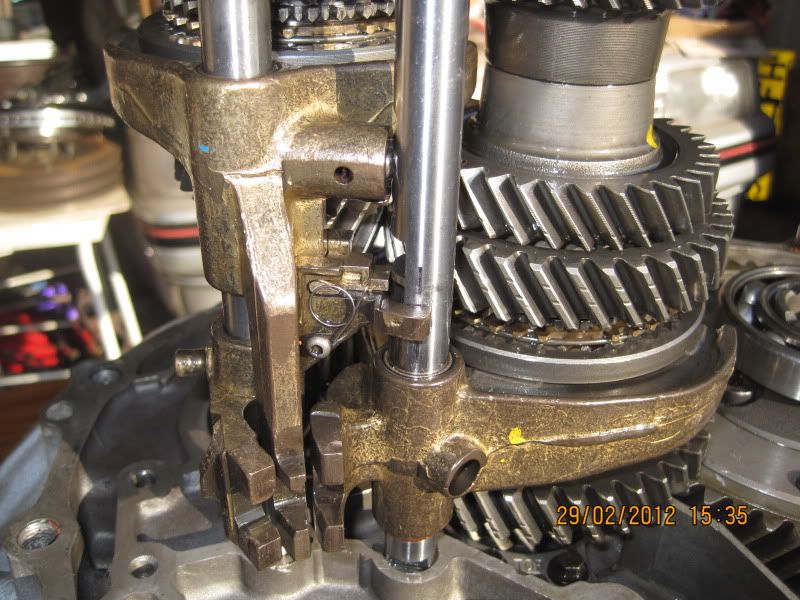

Looking more closely at the selector fork assemblies on this gearbox, they felt a little loose when handling them and something else was different too. There was a small hairspring on the assembly which I'd never seen before. Here it is in this close up picture; right in the middle :~

![Image]()

With these observations in mind, I decided to try a spare set of PG1 selector forks on the cluster in place of the originals. That was after partly dismantling the various components at the top of the Input shaft to check for correct assembly alignment then laid the two shafts ready for the replacement Selector Forks :~

![Image]()

As soon as I fitted the selector forks the whole assembly felt better when it was all in place :~

![Image]()

I lifted it and it went into its locations very smoothly as it should, the exact reverse of the difficult removal process :~

![Image]()

I then removed as much of the black sealant as I could before refitting the casings together. There was a lot of sealant, far more than is really needed and it took quite while to clean it all away. I then placed the casings together and used four bolts only on this dry ( no sealant ) assembly prior to the final test to see if any or all of the gears could now be selected. I inserted the rod into the Roll Pin hole in the gearbox selector shaft stub and set about selecting the gears. First, yes could easily get that and guess what, I could turn the Input shaft using only my bare hand. looking at the differential as i turned the Input shaft, i was pleased to observe the differential rotating as it should for First Gear. same with 2nd, 3rd, 4th and 5th gears.. all not difficult to select and yes, could rotate shaft by hand alone. Now the real problem gear ~ REVERSE. Previously impossible to select. That went in after the first attempt but, required quite a push ~ me still a bit weak after the "flu". Yes, turning the Input shaft again in the same direction, reverse positively identified with the differential rotating in the opposite direction as this few seconds if video clearly shows. Click on the image :~

Appears sorted.

...

Apparently the Box is a Diesel Spec PG1 one with a TorSen differential transplant. The problems, difficulties trying to select some gears. I've been suffering from a strong dose of nasty flu and only this week felt up to humping heavy PG1s about and made a start on Monday. In today's fine sunshine got stuck in and made better progress:~

First things first, found suitable length of rod and inserted that into the Roll Pin Hole of the Box's selector stub shaft :~

Input Shaft very stiff and difficult to manipulate. Impossible to select both 5th and Reverse. Neutral too very imprecise and like a "false" neutral. Even when able to select some gears, impossible to rotate the Input shaft to check :~

Tried again to select all six gears and failed miserably. Shaft very stiff and difficult to manipulate and impossible to select both 5th and Reverse.

Obviously something is not right so started to dismantle and investigate the internals. Removing the various Gearbox Casing Bolts, as soon as I put my socket on this 12mm casing Bolt, it moved.

Hmmm, suspect a stripped thread and so it proved. Someone had "modified it" :~

It should be easy to do that by hand. Could not do that even wearing a glove. Obviously something else not right.

Using a Clutch Plate on the Input Shaft for additional leverage, I was able to rotate the shaft in gear but, required some effort to do so :~

Yes, lots of tight things which should not be tight and impossible to do by hand.

With all the 12mm casing Bolts removed AND the 14mm bolt which secures the Reverse Gear Idler shaft, I was able to seperate the Gearbox Casings to reveal the internals :~

All appeared well so far. With strong gloves, took a firm hold of the two Gear Clusters on their Shafts and the Selector Fork Assemblies and tried to lift them out. A good tug should lift them out ...NO WAY. Very firmly stuck. Using several lengths of rod under the shafts, by patient and careful leverage the assemblies did eventually lift a little at a time and then they were out. I have worked on over a dozen PG1s before and all were far less trouble to lift. Obviously something a bit tight somewhere. With the shafts removed, I looked at the new Input Shaft bearing. Cannot be certain but it did not look quite right. using my fingers it felt a little proud comapred to previous experience with these boxes. anyway, for good measure, used a bit of wood over the outer race and wit a club hammer, gave a few careful taps around its circumference. Not certain but, now it looked better. There was evidence here and close by of previous heavy handedness work on this box. Noticed a few other evidence marks too :~

Looking more closely at the selector fork assemblies on this gearbox, they felt a little loose when handling them and something else was different too. There was a small hairspring on the assembly which I'd never seen before. Here it is in this close up picture; right in the middle :~

With these observations in mind, I decided to try a spare set of PG1 selector forks on the cluster in place of the originals. That was after partly dismantling the various components at the top of the Input shaft to check for correct assembly alignment then laid the two shafts ready for the replacement Selector Forks :~

As soon as I fitted the selector forks the whole assembly felt better when it was all in place :~

I lifted it and it went into its locations very smoothly as it should, the exact reverse of the difficult removal process :~

I then removed as much of the black sealant as I could before refitting the casings together. There was a lot of sealant, far more than is really needed and it took quite while to clean it all away. I then placed the casings together and used four bolts only on this dry ( no sealant ) assembly prior to the final test to see if any or all of the gears could now be selected. I inserted the rod into the Roll Pin hole in the gearbox selector shaft stub and set about selecting the gears. First, yes could easily get that and guess what, I could turn the Input shaft using only my bare hand. looking at the differential as i turned the Input shaft, i was pleased to observe the differential rotating as it should for First Gear. same with 2nd, 3rd, 4th and 5th gears.. all not difficult to select and yes, could rotate shaft by hand alone. Now the real problem gear ~ REVERSE. Previously impossible to select. That went in after the first attempt but, required quite a push ~ me still a bit weak after the "flu". Yes, turning the Input shaft again in the same direction, reverse positively identified with the differential rotating in the opposite direction as this few seconds if video clearly shows. Click on the image :~

Appears sorted.

...