Yes, apart from the obvious, it can give a clue as to what area the problem is which can be helpful.

On any car, a cylinder head gasket can be damaged and still show perfect compression.

On a few occasions I've used my compression tester on engines as different as A-O-S-T and K-series, a single individual low compression reading is more likely to be a warped head, valve, bore, piston and/or rings problems.

If you get identical low readings on adjacent cylinders, that can suggest gasket damage in the area immediately between the two adjacent bores. Last year my son's third of a century old MG Metro [ :yikes: ...

.] started to run rough and compression testing showed very low identical readings on cylinder two and three and healthy ones on one and four. Here's why.

We do not think that gasket actually failed, prolonged lack of use ( years of storage ) in both current and previous ownership probably caused corrosion to set in and then using the car for longer runs blew the weakened fire rings away there in that very narrow area.

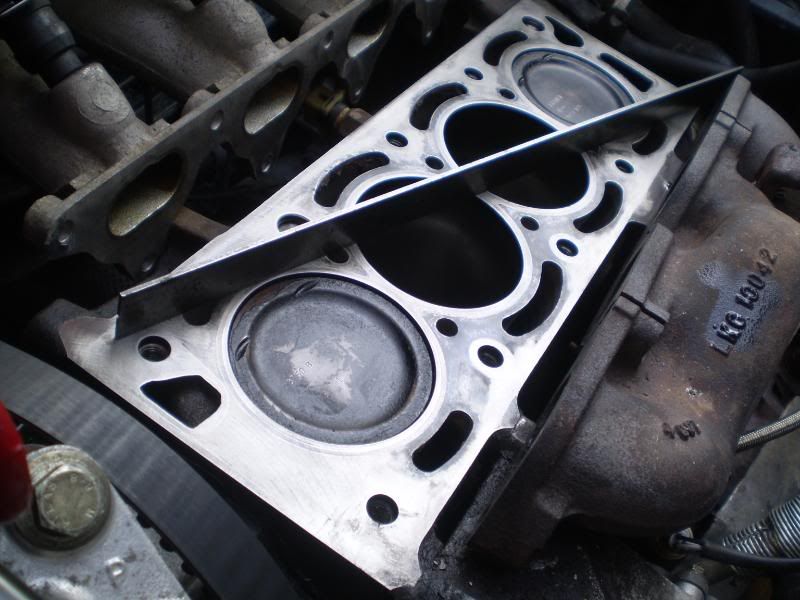

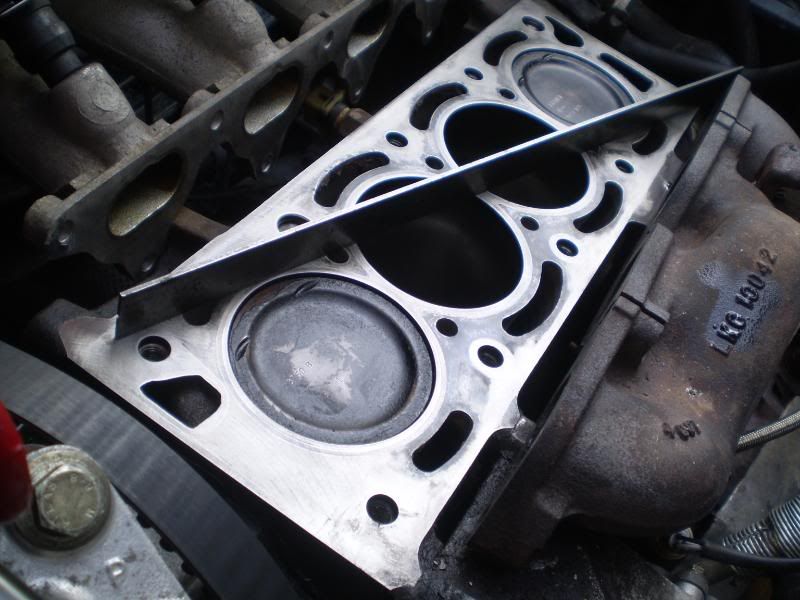

Got near identical low readings on cylinders 2 and 3 on Rover's T series turbo a few years back. The unfortunate previous owner, lovely lady, spent a small fortune on her nice 620ti which still seriously overheated. She gave up and cut losses. I investigated the car and despite a hefty bill which included having the cylinder head, skimmed and dressed, the head was fitted without checking the work. On removal and checking with my straight edge, the head was in a bowed condition ... Using my trusty straight edge on both block and head :~

Revealed this :~

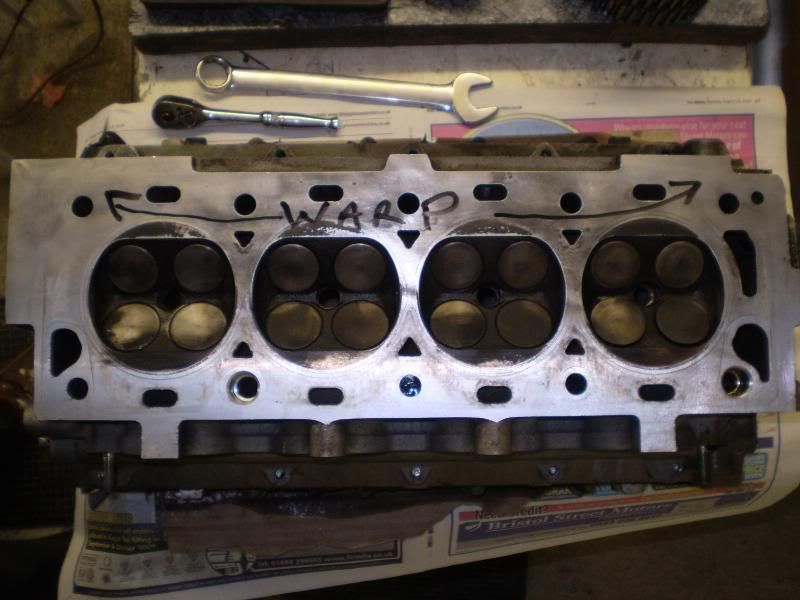

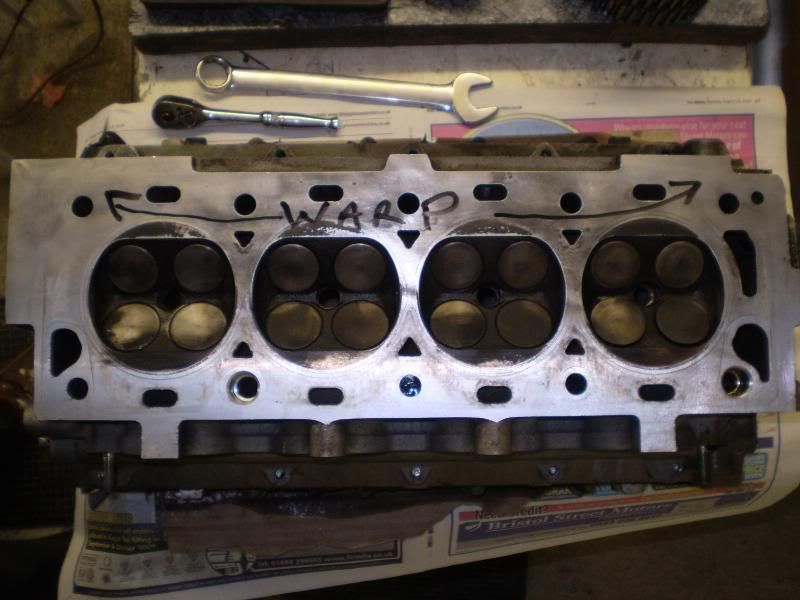

Here is evidence ( Bowed head face ) of exhaust gasses passing the fire rings on middle two cylinders over-pressurising the cooling system once the engine reaches full operating temperature leading to coolant boiling over. :~

Fitted a known good used head and that 620ti became a delightful car to run and own.