Is to sort this non-runner MG ZT 1.8t with suspected cylinder head gasket damage. I accepted ... for me a step into the unknown as I had not heard the car's engine running let alone driven the car!

Anyway as previously posted, got the engine running after fitting the Orange Clip to the realigned parts of the Fuel Filter which had become separated. Frequent problem with this BMW design in-tank Fuel Filter. Not a job I'd like to do again soon but, that Orange Clip is a permanent fix. This is the car and made a good start in the fine weather over the past two days. :~

The car is not actually resting on those two steel wheels and tyres. It's on axle stands and chocked. The wheels are there as a failsafe should the axle stands and chocks decide to let go. Better double safe than sorry as I will be working under that car at times.

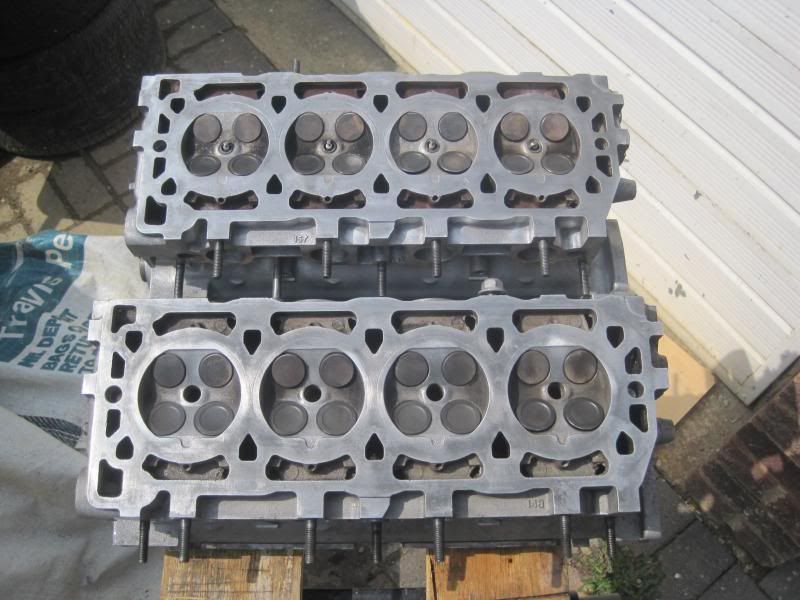

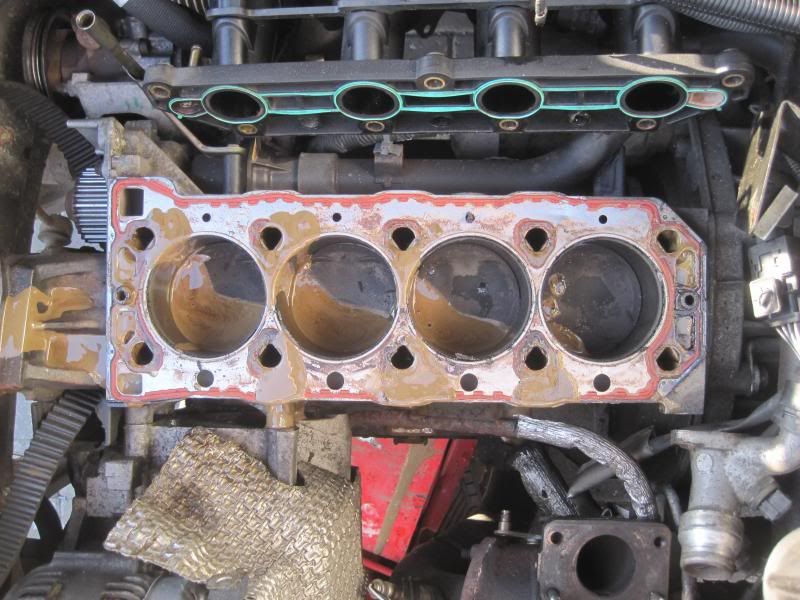

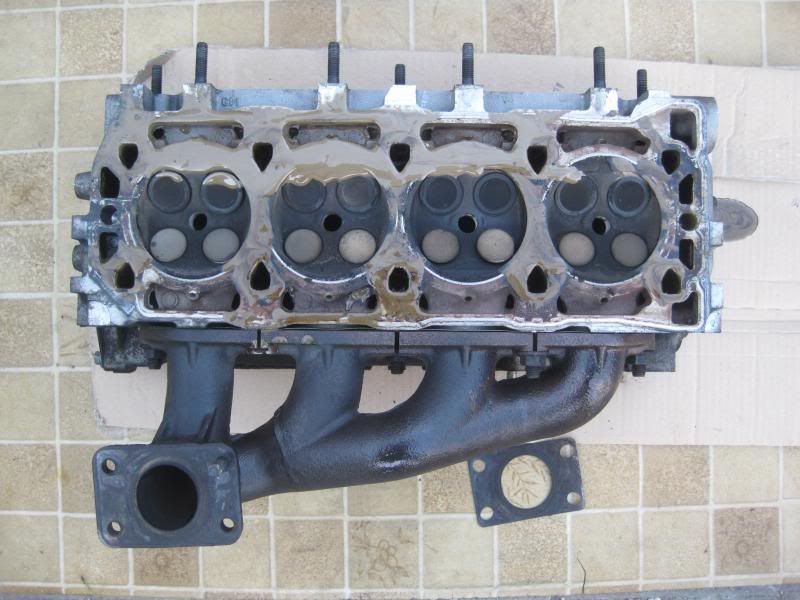

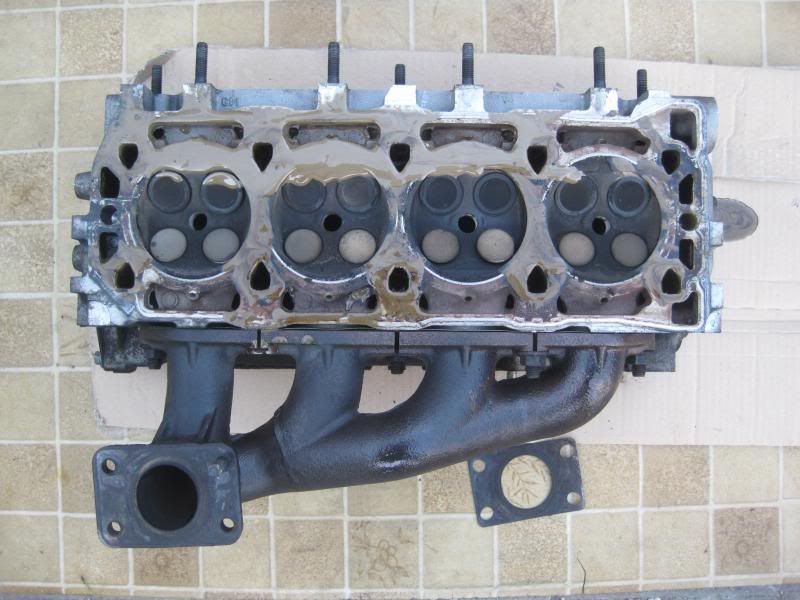

I got the Cylinder Head off ~ bit of a struggle with severely corroded Exhaust Manifold Studs and Nuts. A completely corrosion seized Ex-Manifold Flange to Turbocharger 13mm Flanged Nut had been completely rounded in previous ownership. Needed an angle grinder to break it up. Here is what was revealed :~

There is much more work removing the Cylinder Head on these Turbocharger versions compared to the normally aspirated engines. Lots of additional gubbins in the way to slow progress. Most need to be removed to access other parts essential to remove for the job. Learned a lot today.

Pleased to observe very little signs of Fire Ring Indentation on Cylinder head Face. Just witness marks. That's good :~

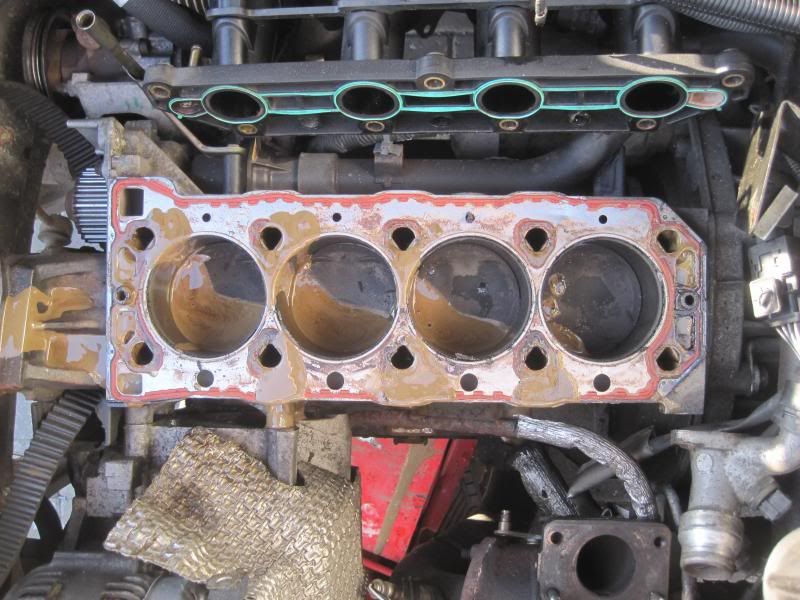

When removing the Oil Filler Cap to do the usual initial check, not much evidence to be seen of cylinder head gasket damage allowing oil-coolant to mix. Until ... Boy of boy did they mix on this engine. Click on image :~

Beware, that bowl I used would normally be ample to collect the whole drained oil contents from any K-Series sump. I had not allowed for the coolant mixed in with the oil which increased the volumeby some margin. My son alerted me just as the bowl was staring to overflow and still stuff coming out. I'm allowing it to drain overnight. Then when engine is all back together, I will buy some Diesel Fuel ( Not actual Diesel Engine Oil ~ Diesel Fuel ) and run that in the engine briefly as it will act like a flushing agent. The inside of that engine and all the coolant passageways will need a couple of flushes once I'm happy the engine is returned to good health. Then dump the Diesel Fuel from the sump and return to recommended 10-40 semi synthetic.

Ongoing ...

Anyway as previously posted, got the engine running after fitting the Orange Clip to the realigned parts of the Fuel Filter which had become separated. Frequent problem with this BMW design in-tank Fuel Filter. Not a job I'd like to do again soon but, that Orange Clip is a permanent fix. This is the car and made a good start in the fine weather over the past two days. :~

The car is not actually resting on those two steel wheels and tyres. It's on axle stands and chocked. The wheels are there as a failsafe should the axle stands and chocks decide to let go. Better double safe than sorry as I will be working under that car at times.

I got the Cylinder Head off ~ bit of a struggle with severely corroded Exhaust Manifold Studs and Nuts. A completely corrosion seized Ex-Manifold Flange to Turbocharger 13mm Flanged Nut had been completely rounded in previous ownership. Needed an angle grinder to break it up. Here is what was revealed :~

There is much more work removing the Cylinder Head on these Turbocharger versions compared to the normally aspirated engines. Lots of additional gubbins in the way to slow progress. Most need to be removed to access other parts essential to remove for the job. Learned a lot today.

Pleased to observe very little signs of Fire Ring Indentation on Cylinder head Face. Just witness marks. That's good :~

When removing the Oil Filler Cap to do the usual initial check, not much evidence to be seen of cylinder head gasket damage allowing oil-coolant to mix. Until ... Boy of boy did they mix on this engine. Click on image :~

Beware, that bowl I used would normally be ample to collect the whole drained oil contents from any K-Series sump. I had not allowed for the coolant mixed in with the oil which increased the volumeby some margin. My son alerted me just as the bowl was staring to overflow and still stuff coming out. I'm allowing it to drain overnight. Then when engine is all back together, I will buy some Diesel Fuel ( Not actual Diesel Engine Oil ~ Diesel Fuel ) and run that in the engine briefly as it will act like a flushing agent. The inside of that engine and all the coolant passageways will need a couple of flushes once I'm happy the engine is returned to good health. Then dump the Diesel Fuel from the sump and return to recommended 10-40 semi synthetic.

Ongoing ...